Measurement controls

Universal measurement control CC17

The highly flexible MEITEC measuring controller for almost every in-process, post-process and preprocessing application with incomparable reaction time.

The measuring controller has a wide range of functions which, depending on the application, can be selected by internal or external parameterization via fieldbus (e.g. PROFINET, PROFIBUS) or digital interface.

Various standard programs for flat finishing and external cylindrical grinding machines (including post-process measurement with control card) simplify commissioning and additional programming of the measuring controller by the user is not necessary.

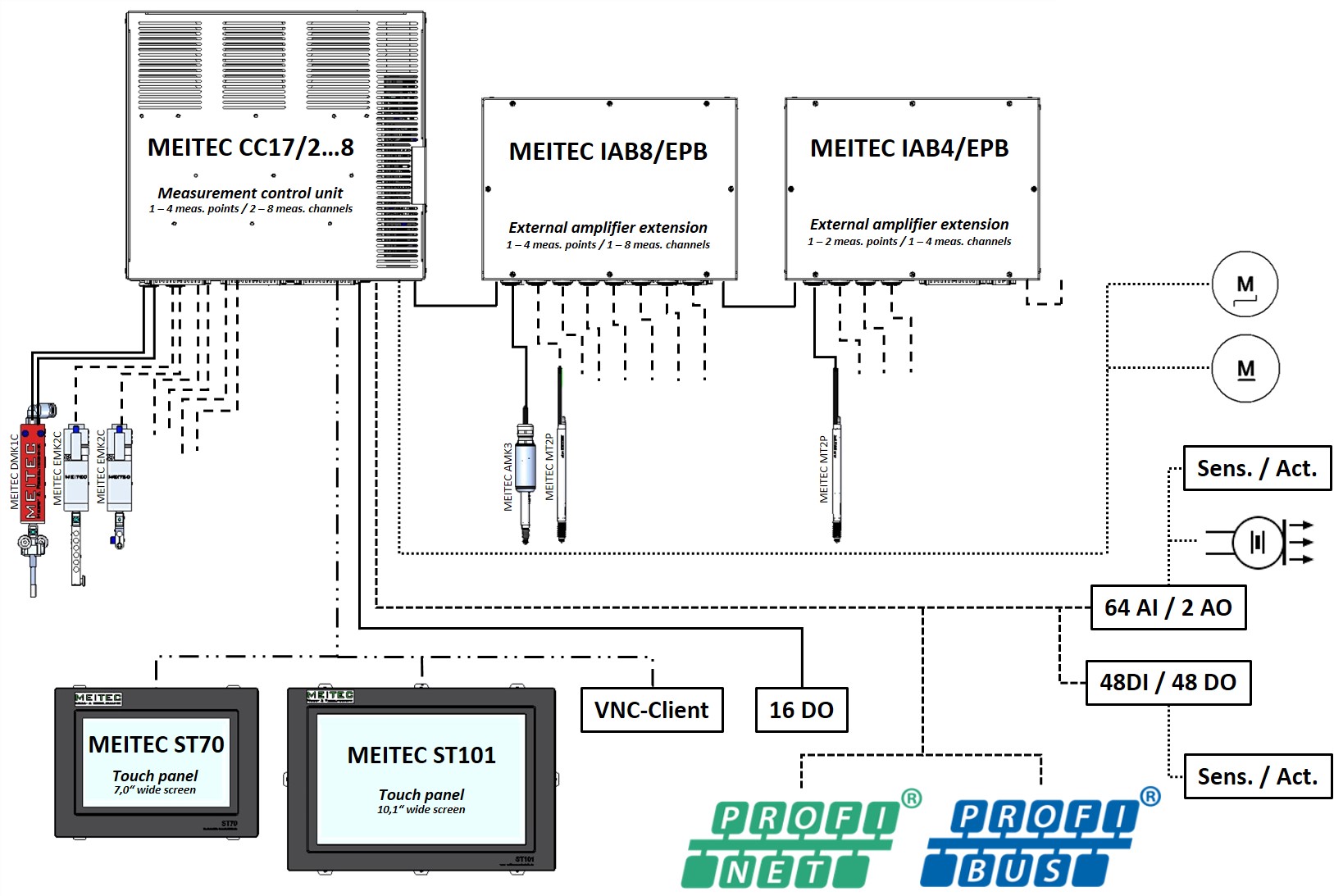

Depending on the version, up to 4 measuring points with a total of 8 measuring channels can be managed internally. In addition, up to 12 measuring points (24 measuring channels) can be realized by external connection of inductive amplifiers of the types MEITEC IAB4/EPB and MEITEC IAB8/EPB.

The visualization and user guidance can be carried out optionally with touch panels of the types MEITEC ST70 (7.0″) and MEITEC ST101 (10.1″) or by VNC transmission to an external visualization system.

The structure of the HMI in clear menus ensures an intuitive and easy handling of the MEITEC measuring controller.

In the process overview screen, up to 8 measuring points are displayed simultaneously with a measured value bar and additional numeric output.

A zero point correction of the respective measuring points can be carried out during measuring operation without having to call up further menus.

In 5 freely programmable x/t diagrams, up to 6 measured values can be displayed in real time (sampling rate 2ms/pixel) during measuring operation.

In all x/t diagrams, analyzes can be performed by means of typical oscilloscope functions (determination of amplitudes and times of the measured values).

By means of an optionally available fieldbus interface (e.g. PROFINET, PROFIBUS), various measured values of all measuring points can be read into the machine controller in parallel or external offsets can be transmitted to the measuring controller. In addition, important process data of the measuring controller can be read or written via the fieldbus.

The internal measurement value conditioning of all interfaces used is always faster than the fieldbus clock, so that at any time updated measured values are available for the machine.

For time-critical applications, the measuring controller has 16 digital outputs as standard, which can, for example, directly affect the “fast inputs” of an NC controller.

All parameterized data can be externally saved on USB storage media and restored.

MEITEC measuring controllers of the type MEITEC CC are highly flexible, allowing a wide range of options (e.g. additional digital or analog I/O, special measurement software functions and, if required, monitoring, control and regulation of additional functions) in order to execute special measuring tasks.

Technical data MEITEC CC17 at a glance:

- Internal 2 … 8-channel measuring amplifier (1 … 4 measuring points)

- 16 digital outputs in the standard scope

- Visualization interface for connecting a MEITEC touch panel MEITEC ST70 or MEITEC ST101

- VNC interface for the realization of a black box operation without MEITEC touch panel, a remote access to the measuring controller or for the connection of a second MEITEC touch panel.

- 1 x USB interface for data backup and creation of screenshots

- 4-level operator concept

- Process data management for 100 process data sets

- Multilingual menu navigation in German, English and special languages

- Operating voltage 24VDC

- Optional external extension with up to 24 measuring channels (12 measuring points)

- Optionally up to 48 additional digital inputs and 48 digital outputs

- Optional PROFINET interface

- Optional Profibus DP interface

- Optional analog input/output interface (current/voltage)

- Optionally further communication interfaces (e.g. Ethernet, CAN)

- Optional control functions (stepper motor, pneumatic cylinder, …)

- Optional visualization functions (structure-borne noise, power, …)

Touchpanels ST70 & ST 101

Technical data MEITEC ST70 at a glance:

- 7.0″ TFT wide screen touch panel in color

- 1 x USB interface for data backup and creation of screenshots

- Operating voltage 24VDC

Technical data MEITEC ST101 at a glance:

- 10.1″ TFT wide screen touch panel in color

- 1 x USB interface for data backup and creation of screenshots

- Operating voltage 24VDC

Extended presentation of the functions of our measuring controller MEITEC CC17:

Compact measurement control ST70-TG

Due to its fully integrated design in a desktop housing, the MEITEC ST70-TG measuring controller is ideal for implementing measuring stations and flexible measuring points. In addition, the compact design offers advantages for retrofit applications in which there are no built-in reserves in the control cabinet or operating panel or the least possible interference should be undertaken with the machine.

Due to its fully integrated design in a desktop housing, the MEITEC ST70-TG measuring controller is ideal for implementing measuring stations and flexible measuring points. In addition, the compact design offers advantages for retrofit applications in which there are no built-in reserves in the control cabinet or operating panel or the least possible interference should be undertaken with the machine.

The MEITEC ST70-TG offers the high standard of the MEITEC measuring functions for up to 4 measuring points (8 measuring channels).

The PROFINET and PROFIBUS fieldbus systems, digital inputs and outputs as well as analog inputs and outputs are available for communication with machine controllers or higher-level systems.

The operation and visualization is carried out via a 7.0″ touch panel with WideScreen resolution.

Depending on the application, the table top measuring controller MEITEC ST70-TG offers the possibility of realizing control and monitoring functions in addition to the pure measuring function, so that often no additional PLC control is necessary at measuring stations.

Technical data MEITEC ST70-TG at a glance:

Technical data MEITEC ST70-TG at a glance:

- 7.0″ TFT wide screen touch panel in color

- Multilingual menu navigation in German, English and special languages

- 1 x USB interface for data backup

- 4-level operator concept

- Process data management for 100 process data sets

- Operating voltage 24VDC

- 2 … 8-channel measuring amplifier (1 … 4 measuring points)

- 16 digital outputs in the standard scope

- Optionally up to 48 additional digital inputs and 48 digital outputs

- Optional PROFINET interface

- Optional Profibus DP interface

- Optional analog input/output interface (current/voltage)

- Optionally further communication interfaces (e.g. Ethernet, CAN)